Category:

Post Date:

Seeing Both Sides of the Story: Why Buyer Reviews + Supplier Self-Reviews Create Stronger, More Transparent Supplier Relationships

Supplier performance programs have matured significantly over the last decade, yet many organizations still rely on a single input: the buyer’s perspective.

While buyer feedback is essential, it represents only half the story.

Suppliers have their own internal view of performance—what they believe is working, where they are improving, and how they think they are delivering value.

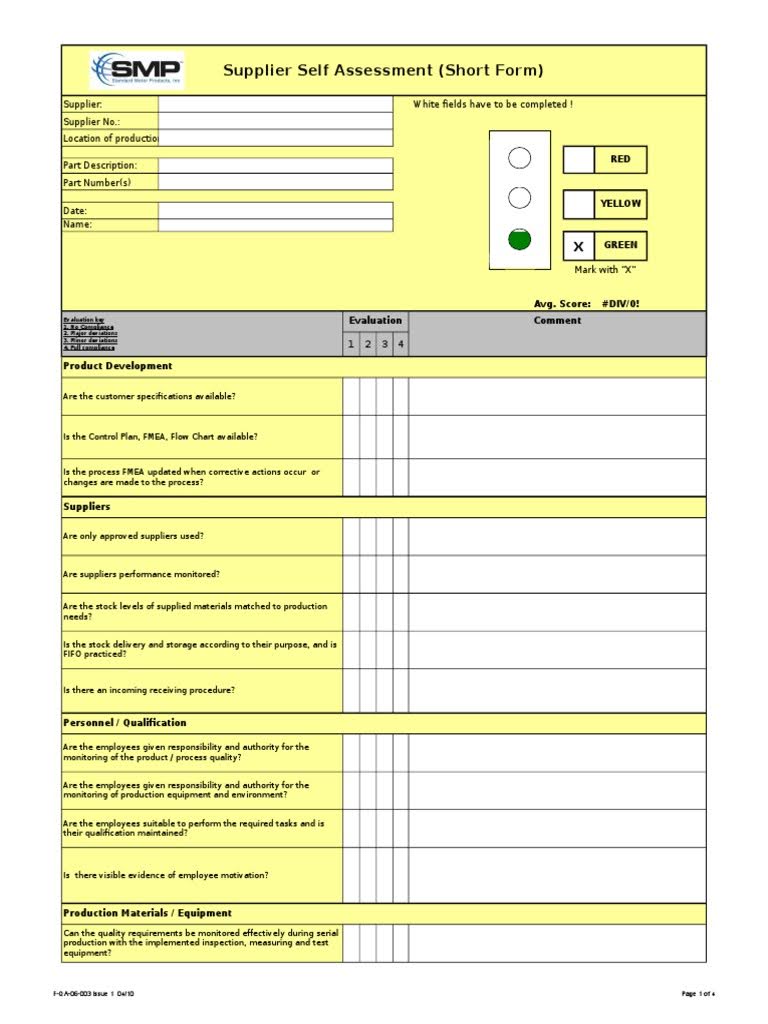

Hive360 bridges these two worlds by allowing suppliers to review themselves using the same performance metrics buyers use. With subtle wording adjustments tailored to the reviewer type, this approach creates transparency, alignment, and more productive improvement conversations.

This isn’t just a feature.

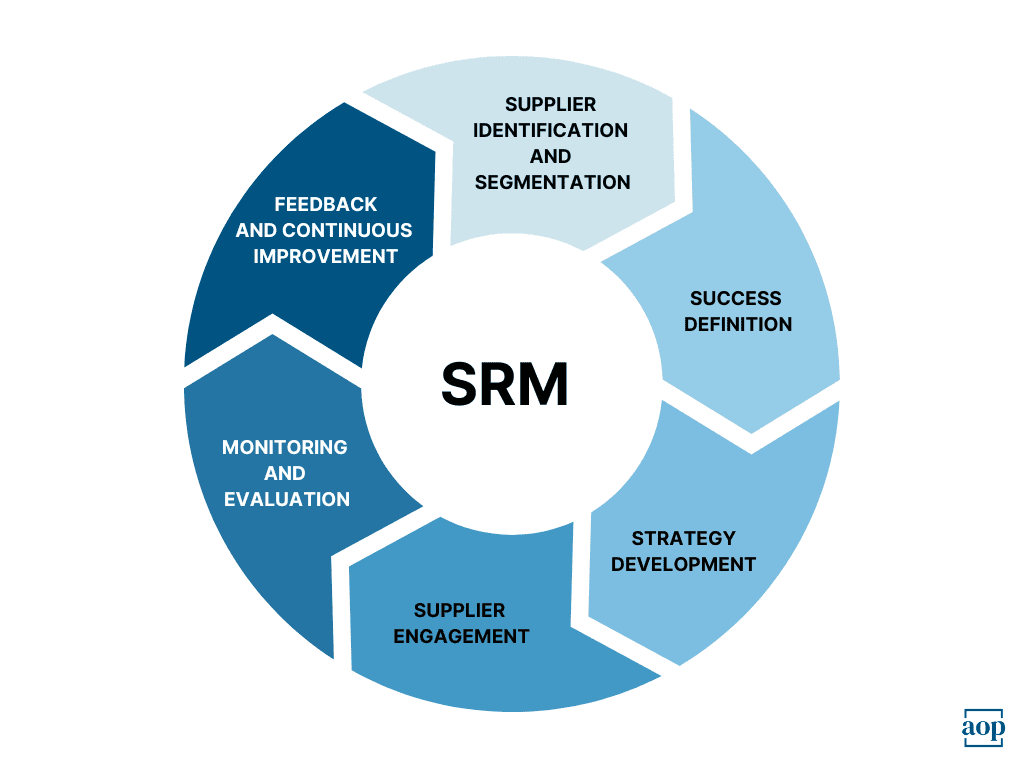

It’s a best practice in modern Supplier Relationship Management (SRM).

Supplier performance programs have matured significantly over the last decade, yet many organizations still rely on a single input: the buyer’s perspective.

While buyer feedback is essential, it represents only half the story.

Suppliers have their own internal view of performance—what they believe is working, where they are improving, and how they think they are delivering value.

Hive360 bridges these two worlds by allowing suppliers to review themselves using the same performance metrics buyers use. With subtle wording adjustments tailored to the reviewer type, this approach creates transparency, alignment, and more productive improvement conversations.

This isn’t just a feature.

It’s a best practice in modern Supplier Relationship Management (SRM).

Why Dual-Perspective Reviews Matter

In traditional Supplier Performance Management (SPM) programs, feedback typically flows in one direction:

Buyer → Supplier

Buyers evaluate performance, suppliers receive scores, and the cycle repeats.

The problem?

Suppliers often believe they are performing better than buyers think—not because they are ignoring issues, but because they lack visibility into:

In traditional Supplier Performance Management (SPM) programs, feedback typically flows in one direction:

Buyer → Supplier

Buyers evaluate performance, suppliers receive scores, and the cycle repeats.

The problem?

Suppliers often believe they are performing better than buyers think—not because they are ignoring issues, but because they lack visibility into:

- Internal frustrations on the buyer side

- Performance expectations that were never clearly communicated

- Evolving buyer priorities

- Experience gaps across different stakeholders

- Buyer wording: “How is it working with the customer service team at Supplier Name?”

- Supplier self-review wording: “How do you think your customer service team is doing?”

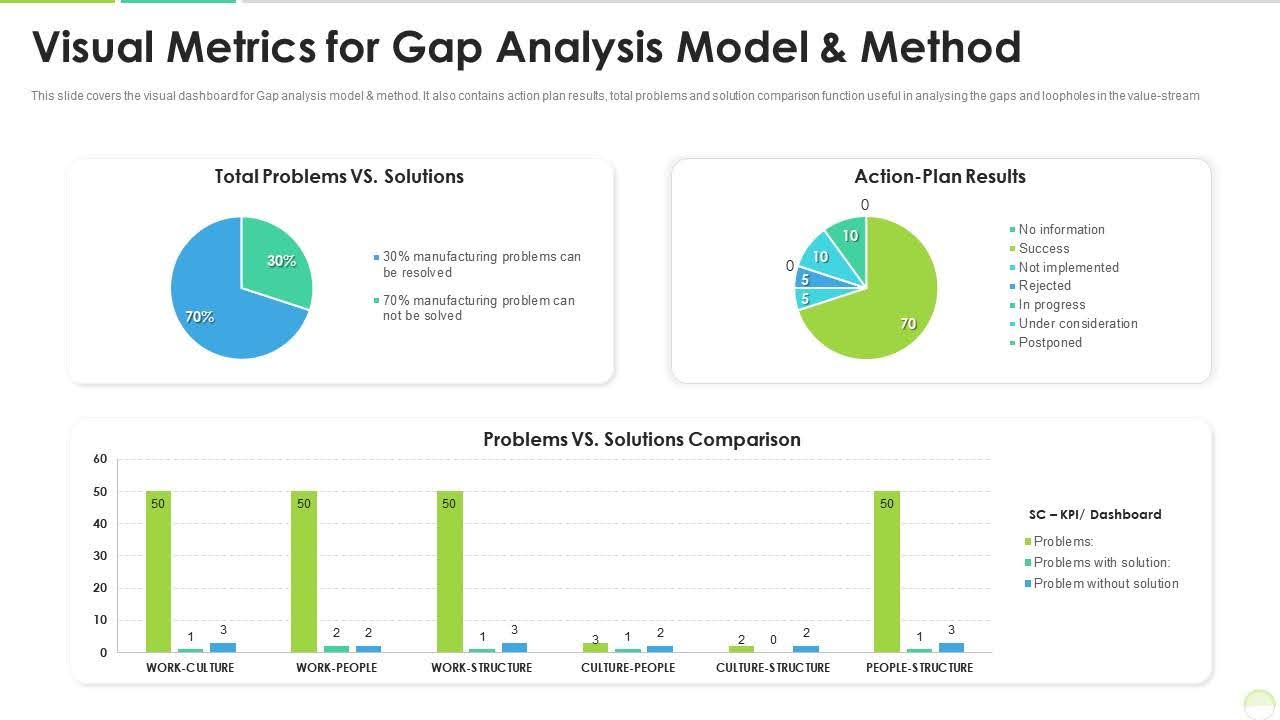

The Power of Perception-Gap Visualization

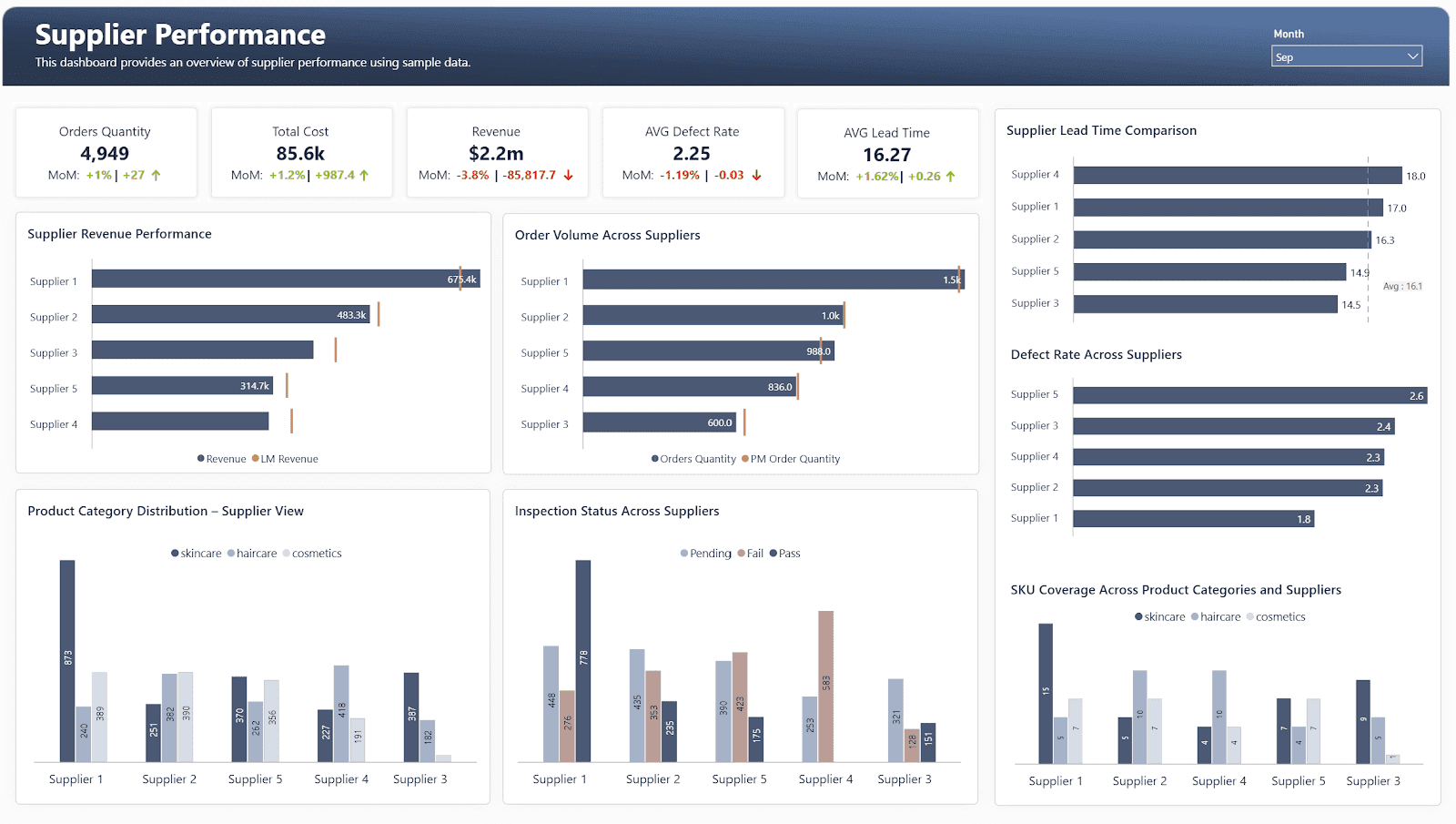

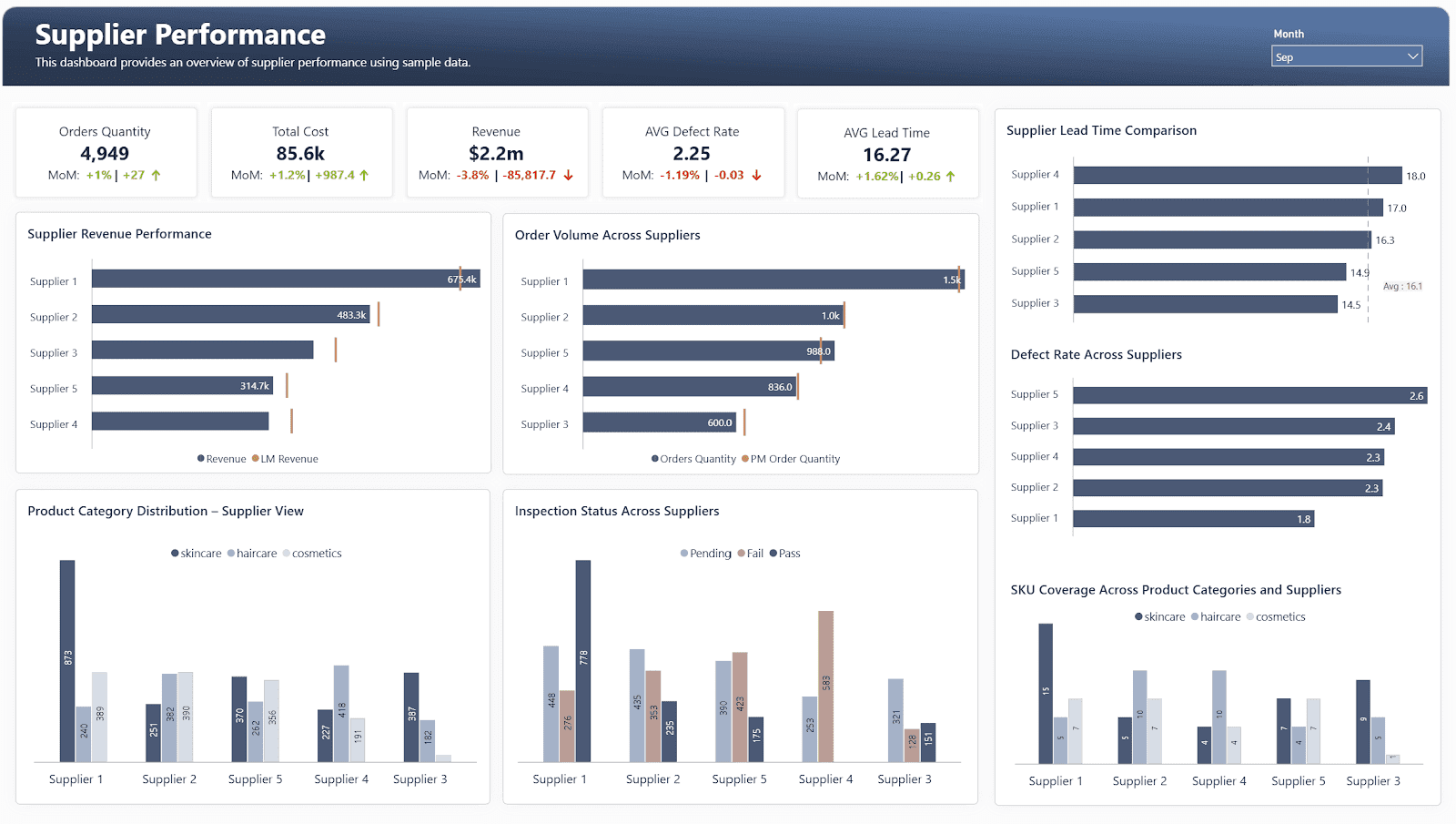

Once both perspectives are captured, the real value emerges through visualization.

Once both perspectives are captured, the real value emerges through visualization.

Early Detection of Misalignment

A supplier may believe their delivery, communication, or quality performance is excellent, while buyers experience delays, unclear handoffs, or inconsistencies. Seeing a clear gap—for example, a high supplier self-score alongside a significantly lower buyer score—immediately signals where attention is needed.Objective, Data-Driven Conversations

Instead of emotionally charged discussions, teams can now say:- “Here’s where you believe performance is strong.”

- “Here’s where we see challenges.”

- “Let’s explore why these views differ.”

Tracking Supplier Maturity and Self-Awareness

Suppliers whose self-ratings consistently exceed buyer ratings often reveal blind spots. Suppliers whose ratings closely align with buyer feedback typically demonstrate stronger governance, accountability, and partnership maturity. This insight reflects not just performance—but relationship health.Smarter Prioritization of Development Efforts

Perception-gap visuals help identify:- Minor misalignments that need light correction

- Major gaps requiring immediate action

- Areas where both sides agree performance is strong

- Situations where misunderstanding—not failure—is the root cause

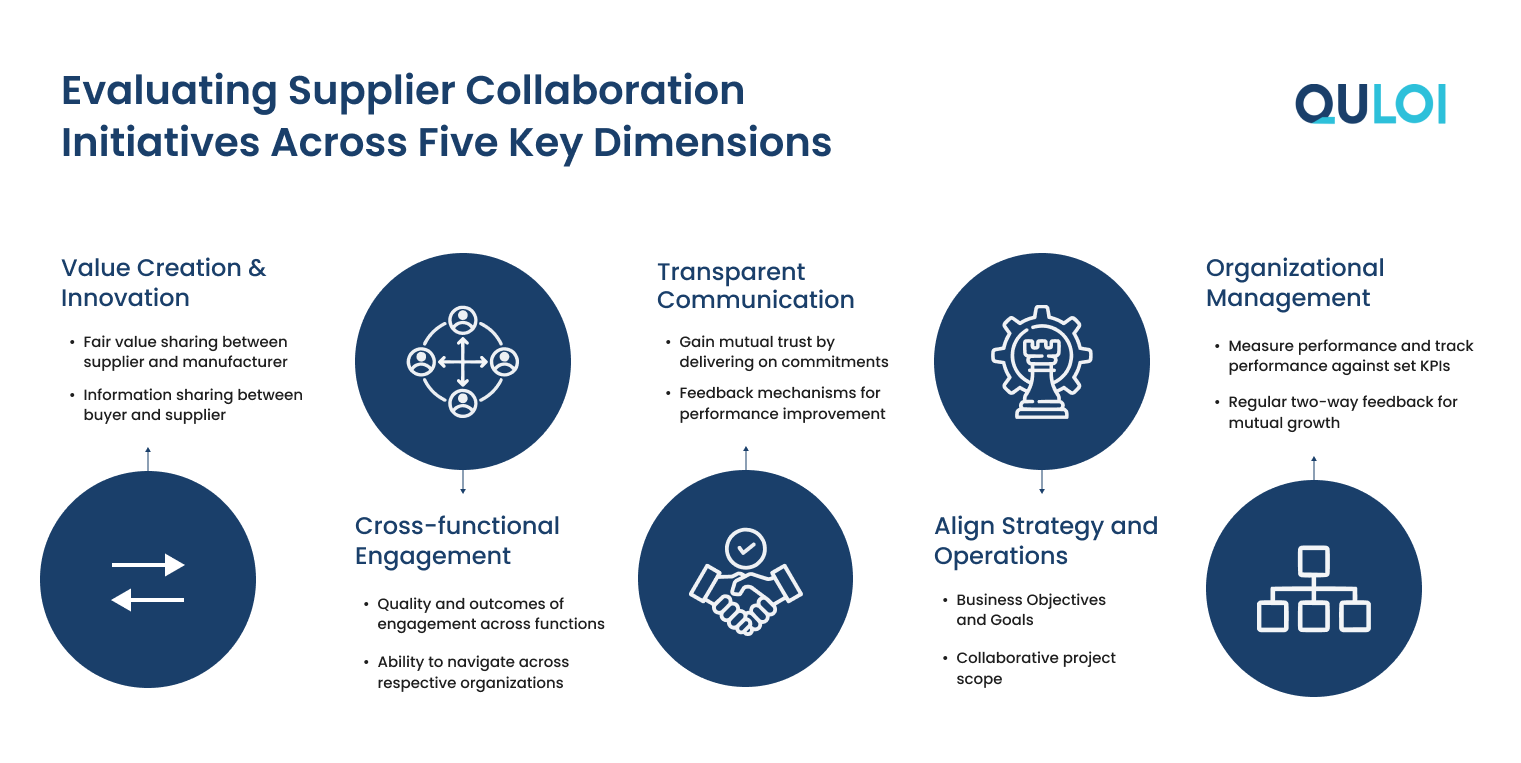

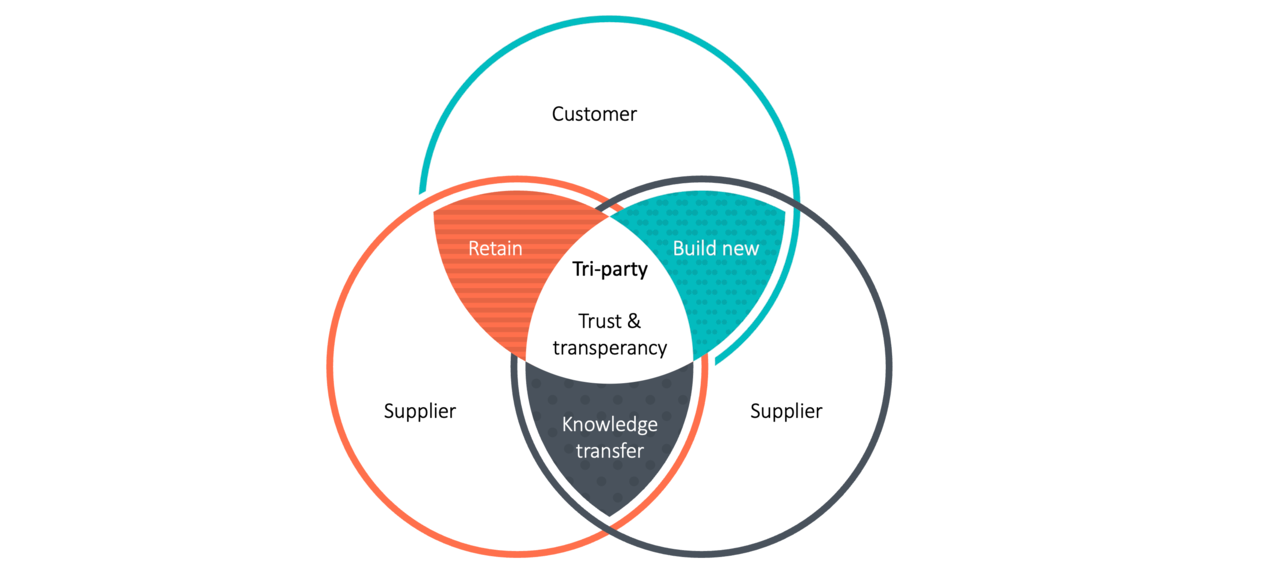

Why This Methodology Builds Stronger Supplier Relationships

Healthy supplier relationships are built on transparency, shared expectations, and ongoing dialogue.

Healthy supplier relationships are built on transparency, shared expectations, and ongoing dialogue.

Suppliers Feel Heard

Most suppliers rarely get structured opportunities to assess themselves. Self-reviews give suppliers an equal voice, fostering engagement, accountability, psychological safety, and shared ownership of outcomes.Buyers Gain Context Beyond the Metrics

Supplier self-assessments often reveal:- Behind-the-scenes investments

- Challenges buyers were unaware of

- Process improvements underway

- How suppliers genuinely perceive their performance

Reduced Friction and Increased Trust

When perception gaps are surfaced transparently:- Defensiveness decreases

- Openness increases

- Conversations focus on root causes

- Trust grows through shared understanding

Why Dual-Perspective Reviews Are Becoming an SRM Best Practice

Organizations are increasingly adopting this approach because it:- Delivers more accurate performance assessments

- Improves engagement on both sides

- Supports continuous improvement

- Reduces disputes and miscommunication

- Strengthens long-term partnerships

- Enables data-driven QBRs and strategic planning

How to Use Dual-Perspective Reviews Effectively

Keep Wording Consistent

Make small phrasing adjustments while preserving metric equivalence.Visualize Gaps, Not Just Scores

Misalignment visuals drive deeper insight than ratings alone.Use Reviews as Conversation Inputs

Bring insights into QBRs, category reviews, and planning sessions.Frame Gaps as Opportunities

Position differences as learning moments—not failures.Track Alignment Over Time

The goal is steady convergence, not instant agreement.Conclusion: Seeing Both Sides Creates Stronger Supplier Partnerships

SPM programs succeed when they provide a complete and honest picture of performance. By combining buyer reviews with supplier self-assessments—and clearly visualizing perception gaps—organizations gain deeper insight into how suppliers are truly performing. This approach drives:- Better decision-making

- Healthier relationships

- Greater transparency

- Stronger long-term value creation